The compaction decision window

The Compaction Decision Window - Timing is the problem

The Compaction Decision Window Closes Earlier Than Most Teams Realize

Most compaction workflows assume that feedback arrives in time to change outcomes.

Density is measured. Results are reviewed. Lessons are learned.

But by the time that feedback becomes available, the opportunity to influence compaction outcomes has often already passed.

On most asphalt paving projects, rollers have moved on, the mat has cooled, and crews are preparing for the next section before density results are reviewed in detail. At that point, outcomes are no longer adjustable—they are simply documented.

The moment that actually matters

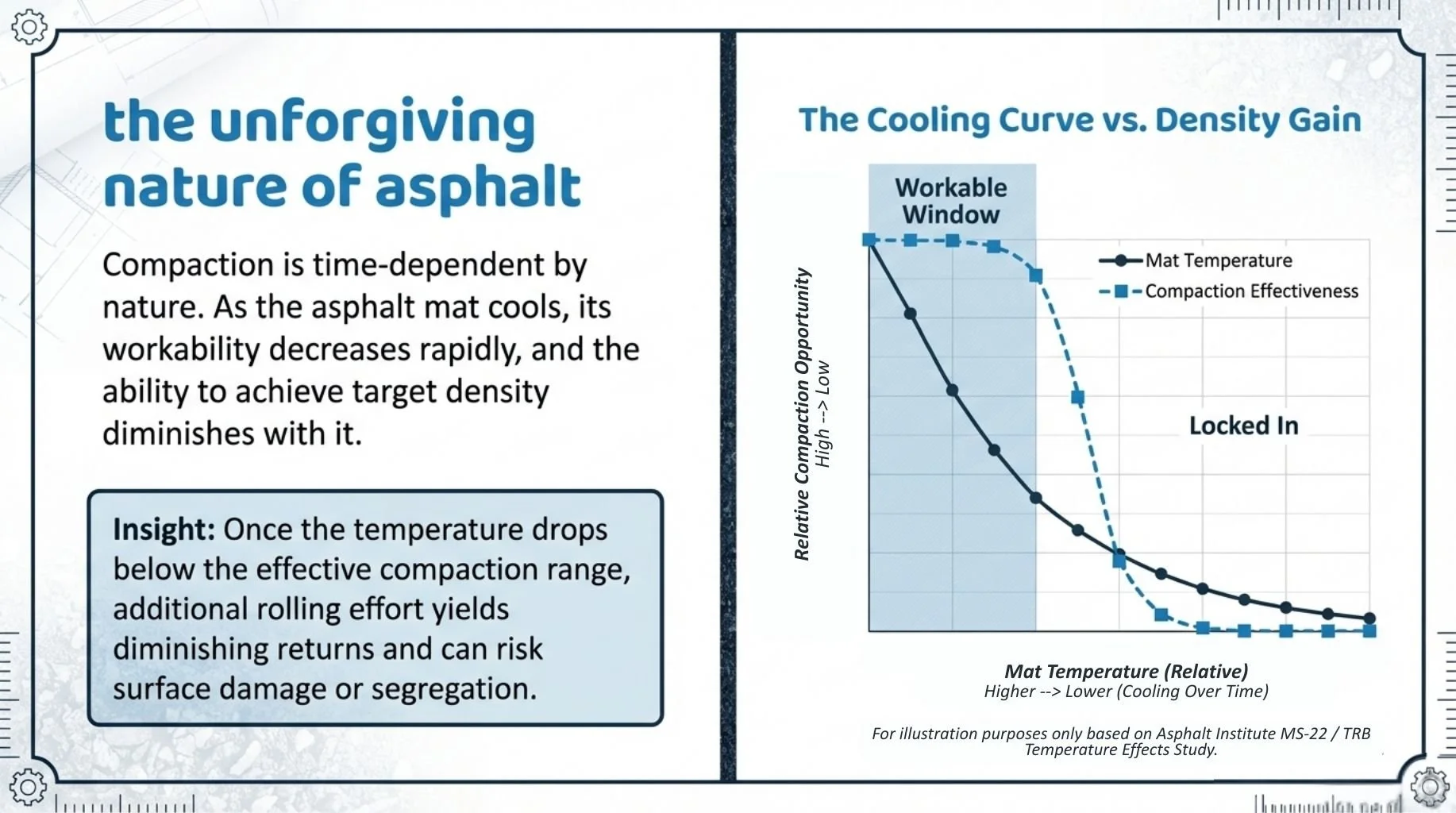

Asphalt compaction is time-dependent by nature. As the asphalt mat cools, its workability decreases rapidly, and the ability to achieve target density diminishes with it. This behavior is well documented in both industry guidance and research.

What matters operationally is not whether density can be measured accurately, but whether information arrives while the mat is still compactable.

Once temperature drops below the effective compaction range for a given mix, additional rolling effort yields diminishing returns and can even risk surface damage or segregation.

The missed assumption in many workflows

Many quality control workflows are structured around verification, not intervention.

They are designed to answer questions like:

Was target density achieved?

Did the section meet specification?

Can results be documented and defended?

Those are important questions—but they are inherently retrospective.

They assume that learning after the fact is sufficient to improve outcomes on the next pass, the next pull, or the next job. In practice, that assumption breaks down when conditions change within minutes, not days.

Decision windows are short—and local

Compaction decisions are made:

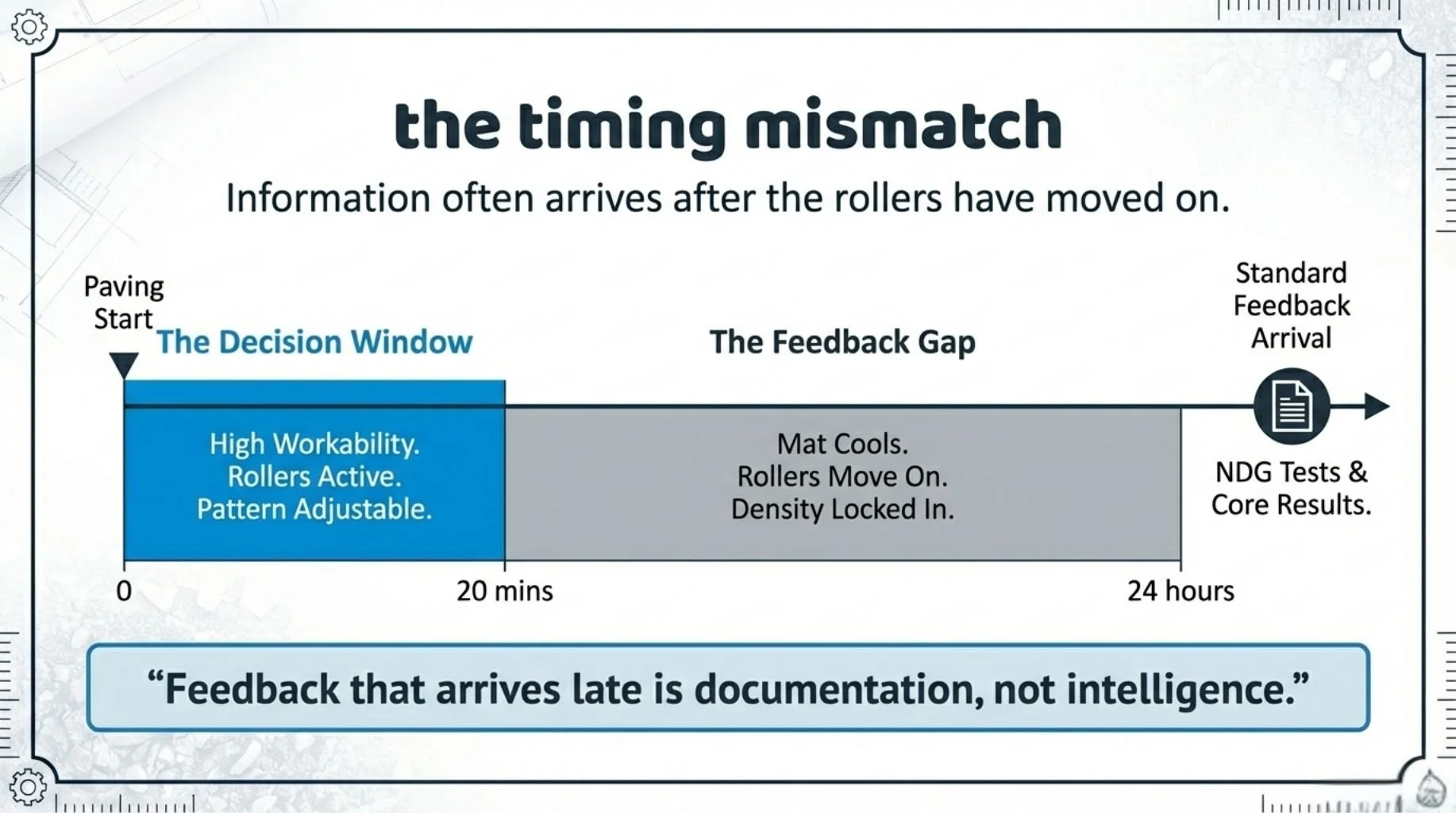

The timing mismatch

While the mat is still within a workable temperature range

While rollers are actively operating on the section

While adjustments to rolling pattern, speed, or coverage can still influence results

This decision window is measured in minutes, not shifts or days.

Feedback that arrives outside that window may still be accurate—but it is no longer actionable for that section.

Why this matters

When compaction feedback arrives too late:

Density variability becomes visible only after it is locked in

Pay Factor outcomes are determined before they are reviewed

Rework, disputes, or corrective actions become administrative rather than operational

None of this implies poor workmanship or insufficient effort. It reflects a timing mismatch between when decisions are made and when information becomes available.

Reframing the problem

This is not primarily a measurement problem.

It is a timing problem.

Improving compaction outcomes requires aligning information delivery with the moment when crews can still act—while the asphalt is still workable and decisions still matter.

When does your compaction information arrive relative to when decisions are actually made in the field?

Ready to learn more? Get in touch at info@compactica.com

References

Asphalt Institute. MS-22: Construction of Hot Mix Asphalt Pavements.

Federal Highway Administration (FHWA). Intelligent Compaction: A Practical Guide for Asphalt Pavements (FHWA-HIF-19-050).

NAPA. Best Practices for Intelligent Compaction.

TRB. Temperature Effects on Asphalt Compaction and Density Development.