How Real Time Compaction Visibility Improves QA for Earthwork Contractors

Most earthwork contractors only see a small fraction of what is happening under the roller. Traditional compaction testing checks a few isolated points in each section, sometimes less than 1% of the total compacted ground. This limited coverage is one of the biggest gaps in QA and one of the leading causes of failed tests and rework.

According to the Federal Highway Administration, up to 50% of major infrastructure projects experience geotechnical related cost or schedule impacts (FHWA, 2020) . Weak areas often go unnoticed until the final QC test is taken, and by then the rework is costly and slows down the crew.

Real time visibility changes that. By combining sensors with algorithms and AI models that read how the soil behaves under the roller, crews finally get a complete picture of their compaction as it happens. Operators know where the ground is responding well, where it needs more work, and when it is ready to move on.

Below are the core ways real time visibility improves QA outcomes.

1. It reduces failed compaction tests

Density tests represent a small area and do not reflect the full condition of the section. When only a few points are measured, soft zones remain hidden until the QC test. This leads to failures, delays, and extra passes long after the operator has moved on.

Studies show that density measurements cover less than 1% of the compacted area (NCHRP, 2012) . By contrast, real time visibility shows compaction response across 100% of the ground. Operators can find and fix weak spots early instead of being surprised later.

Traditional Compaction Testing with NDG

2. It allows adjustments while the soil is still workable

With real time data, operators can:

add passes where the soil is not responding

reduce passes where stiffness increases

identify soft pockets instantly

avoid overworking or underworking sections

This eliminates wasted time and prevents operators from unknowingly leaving behind areas that will later fail a QC test.

3. It gives QC teams a complete, defensible record

Documentation gaps are one of the primary drivers of disputes. 66% percent of geotechnical claims stem from unforeseen ground condition issues tied to missing documentation (HKA CRUX Report, 2023) .

Real-time visibility solutions automatically log:

roller location

soil behavior

stiffness response

number of passes

timestamps

GPS tags

Instead of handing over a few test results, contractors can provide a continuous record that stands up during review.

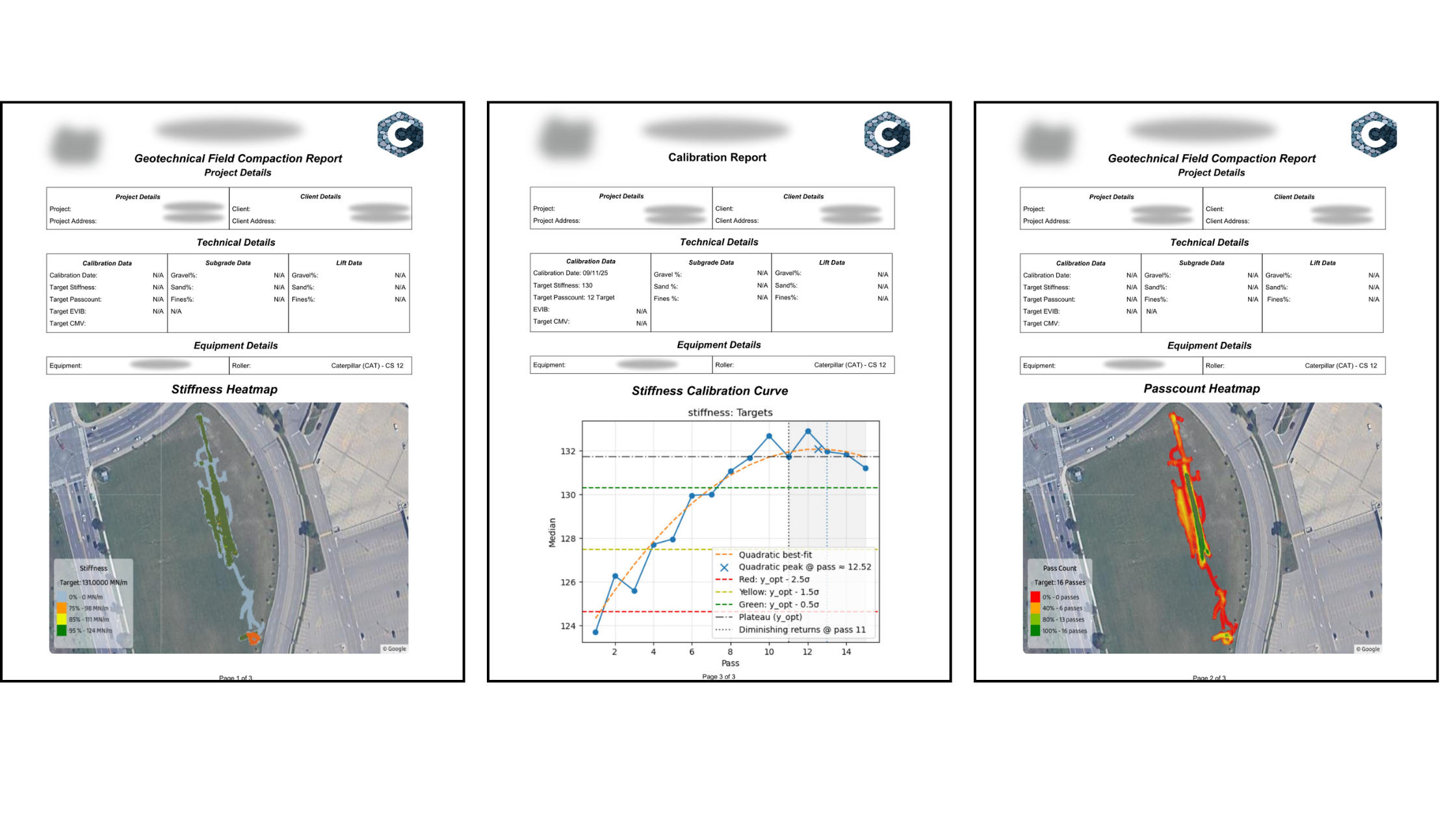

Intelligent Compaction Sample Reports

4. It handles changing soil conditions

Soil behavior shifts quickly with:

moisture

temperature

weather

cold ground or frozen layers

changes in fill material

AI models can interpret the soil response in these conditions and show how each pass is affecting the ground. This is critical because uncontrolled variations in moisture content are a leading source of compaction variability (USBR, 2019) .

5. It improves productivity and keeps the job moving

Real time visibility reduces uncertainty that slows crews down. When operators know what the ground is doing, they work more efficiently and confidently.

Benefits include:

fewer unnecessary passes

fewer failed QC tests

faster movement between sections

quicker sign off

reduced rework

This is why multiple state DOTs and contractors across North America have cited improved productivity when using continuous compaction data (MnDOT, 2020) .

Final Thoughts

Real time compaction visibility closes one of the largest gaps in QA. By showing crews how the ground is responding as they work, contractors reduce risk, speed up approvals, and build stronger documentation without slowing down production.

References

Federal Highway Administration (2020). Geotechnical Risk in Infrastructure Projects

NCHRP (2012). Accuracy of Spot Density Testing and Compaction Coverage Studies

HKA CRUX Report (2023). Global Construction Disputes Analysis: Ground Condition Claims

United States Bureau of Reclamation (2019). Soil Moisture Impact on Compaction Variability

Minnesota Department of Transportation (2020). Intelligent Compaction Field Trials and Productivity Impacts